3D Printing Statistics (2022 Additive Manufacturing Data)

Posted by Rob Errera on 06/10/2022

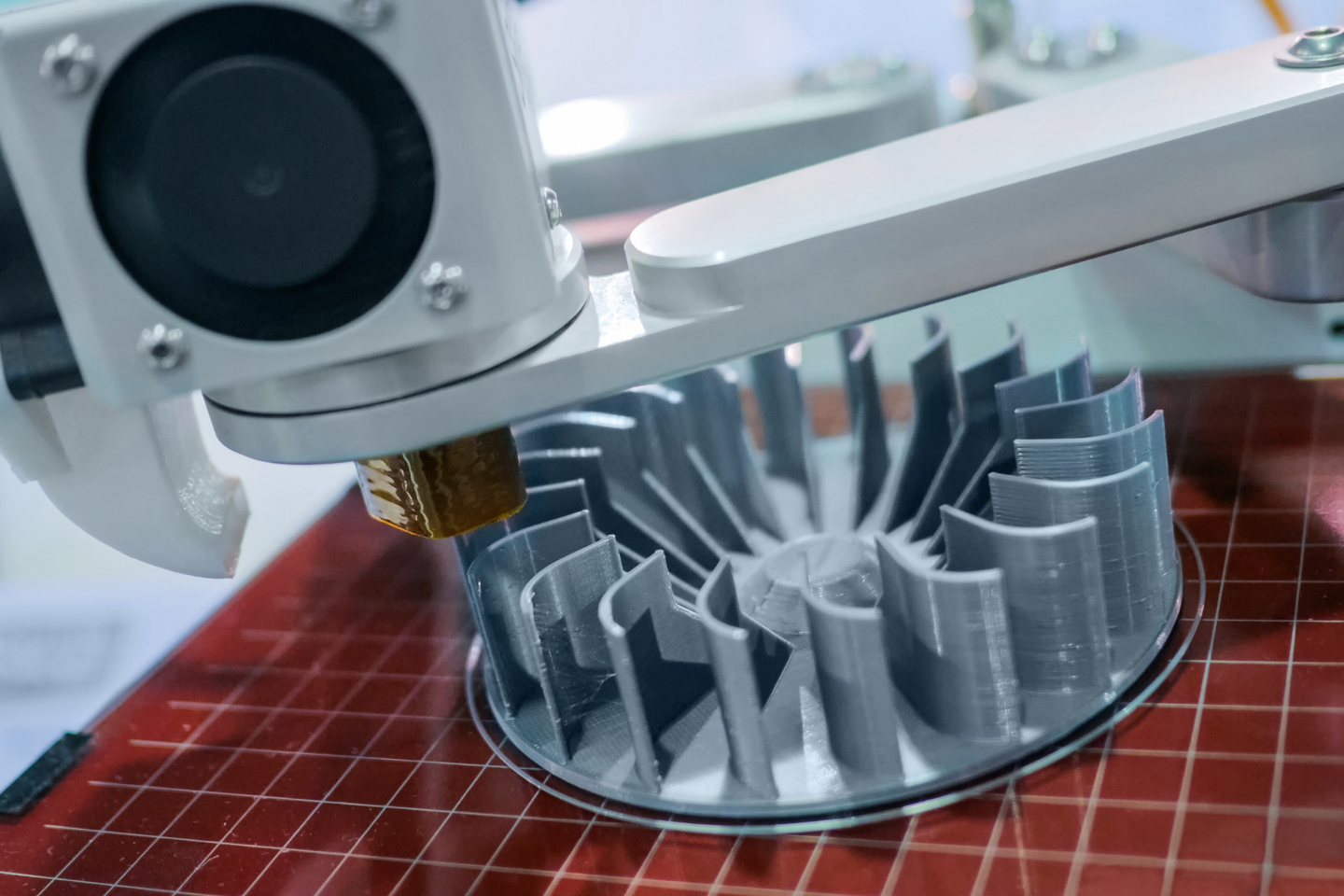

3D printing is booming. Intricate parts and products are 3D printed around the world, layer by layer, using a process called additive manufacturing (AM).

From customized pieces for automobile interiors, spacecraft engines, face shields and masks for healthcare workers, to creative pen holders, 3D printing is becoming an integral part of worldwide manufacturing.

Let’s take a glance at the latest 3D printing statistics and industry data.

3D printing is great for prototyping and creating unique industry solutions.

The 3D Printing Industry Statistics

- The global 3D printing market reached a value of $13.8 billion in 2021.

- The value of the North American 3D printing market in 2021 was $5.72 billion.

- Various analysts predict that the 3D printing industry will grow at staggering speeds – between 18% and 27% per year.

- About 2.2 million 3D printer units were shipped in 2021.

- Equipment costs more: The 3D printing equipment market was valued at $4.5 billion in 2021, while the materials market was $1.7 billion.

- The most profitable 3D printer manufacturers are AutoDesk, HP Inc., 3D Systems, Desktop Metal, and Proto Labs. The market value of AutoDesk is above $68.2 billion.

- Investors understand the hype: back in 2018, VC funding for 3D printing start-ups surpassed $300 million.

- Companies that already utilize 3D are hooked too: over 23% reported investing more than $100K into 3D printing tech in 2020.

- When asked about the benefits 3D printing has over other production methods, 69% of respondents say they use it for its outstanding ability to create complex geometrical objects, 52% value the quick iteration of products, and 41% claim its mass customization abilities are important.

- Out of companies that utilize 3D printing technologies, 38% consider it their main activity, while another 18% have in-house departments dedicated to it, and 16% use 3D print across multiple departments.

Most Used 3D Printing Technologies

- Fused deposition modeling (FDM) or fused filament fabrication (FFF), such as HP's Multi Jet Fusion, is the most established 3D printing technology in the market. Out of companies that use FDM / FFF, 71% use the technology in-house.

- Selective laser sintering (SLS) is the second favorite. However, the majority of its users, 42%, use it as an external service.

- Stereolithography (SLA) used to lead as a major technology in the past, but it's quickly getting replaced by quicker technologies. In 2020, the SLA market size was evaluated at $1.6 billion.

- Metal 3D printing is becoming more popular by the day, as industries around the world face rising concerns over the use of plastic. In 2018, 65% of 3D printers used plastic, and 36% used metal.

What is 3D Printing Used For?

- Many industries are adopting 3D printing: it’s broadly used in aerospace, automotive, and healthcare industries. For example, Boeing uses industrial 3D printing to make plane interior elements, NASA uses 3D printed elements in satellites and engines, and rapid tooling and interior customization bloom in the automobile industry.

- With 3D printing in healthcare valued at $1,036 million in 2020, healthcare benefits from 3D printing: it’s widely used to make personal protection equipment (life-saving in light of COVID-19 shortages), surgical drill and cutting guides, and customized prosthetics (especially in dentistry) and organ replicas.

3D printed plastic cast for broken hand.

- Many types of materials can be 3D printed – all kinds of plastics, resins, metals, cement, and even a sort of ceramic. People even 3D-print food for gourmet dining. The concept is simple - food like chocolate and purees, intricately shaped using additive manufacturing. The 3D food industry thrived in 2021 – reaching $76.9 million.

- Out of companies that reported significant investments in 3D printing tech, 70% use it for small series, 49% for large series, and 18% report mass production.

- The sportswear company Adidas is among those that mass produces 3D printed products – their 4DFWD running shoes feature 3D printed soles.

- Over 68% of companies that use 3D printing use it for prototyping and pre-series manufacturing.

- The prototyping value of 3D printing was estimated at $4.4 billion in 2020.

- Proof of concept is the second leading use with 59% of respondents saying they utilize it in 2020.

- Out of companies that use 3D printing, 40% create 3D-printed functional parts, and 26% print tools.

- 27% of companies that use 3D printing use it to create end-user consumer goods.

- The molds and tooling sector is expected to grow from a value of $5.2 billion in 2020 to $20 billion within the next ten years.

Limitations and Growth Opportunities of 3D Printing

- Many companies believe that 3D printing can help improve the flexibility of their supply chains: 55% of surveyed companies believe it can simplify their logistics, transport, and inventories. With 3D printing, it’s becoming a real option to ship actual products as digital files!

- 69% of 3D printing users agree: 3D printing needs to grow more reliable as a technology, and have a lower cost of entry. In fact, 29% of responders claim that the lack of confidence in the reliability of 3D printing is a major deterring factor on a per-project basis.

- Up to 71% of companies feel they lack the knowledge or training to efficiently use 3D printing technology.

- It’s clear that the 3D printing market is constrained by the high costs of both the tech and materials.

- Speed and scalability are two big limiting factors that slow the rate at which certain industries adopt 3D printing. For example, an aerospace company may only need 100 components a month, but a car manufacturer would need thousands. This limitation translates quite directly: The automotive sector sees the slowest growth in widespread adoption among major industries that utilize 3D.

- Some analysts raise concerns about the traditional forms of intellectual property protection with the rise of 3D printing.

- International 3D printing standards, quality assurance and control are the next challenges the 3D market needs to overcome. Governing bodies will likely need to tackle the issue of international standards and quality control in the near future.

Wrap Up

3D printing is a huge world of potential – and companies across the globe are starting to recognize that.

With a wider reach of 3D technologies, a bigger focus on education can boost the industry even further.

Better training and more comprehensive knowledge base are bound to increase the companies’ confidence in practical applications of 3D printing.

So, it’s no wonder universities around the world are including 3D printing engineering in their curriculums.

In addition, the rapid evolution of 3D printing will need to cross one more obstacle for faster development: printing speed. But with the growing investment in 3D printing startups, we’ll surely get there soon!

Further Reading:

- How To Print on Fabric - The Freezer Paper Method

- Our Eric Clapton Replica Guitar Made With Toner

- Staggering E-Waste Facts & Statistics 2022

https://www.globenewswire.com/en/news-release/202...

https://amfg.ai/2020/01/14/40-3d-printing-industr...

https://all3dp.com/2/3d-printed-food-3d-printing-...

https://www.statista.com/statistics/560304/worldw...

https://www.fortunebusinessinsights.com/industry-...

https://www.futuremedicine.com/doi/10.2217/3dp-20...

https://formlabs.com/blog/3d-printing-materials/

https://news.adidas.com/running/4dfwd--data-drive...

https://www.statista.com/statistics/560271/worldw...

https://www.jabil.com/blog/overcoming-top-3d-prin...

https://www.ey.com/en_us/advanced-manufacturing/h...

Calculating arrival date

Calculating arrival date