How To Print on Fabric - The Freezer Paper Method

Posted by Rob Errera on 10/18/2021

Let’s face it — staying shuttered up at home is boring. Want to do something fun and creative during COVID quarantine? Fire up your printer and let’s get to work!

Laser toner isn’t just for printing clear, sharp text and images! Creative types are finding inventive new uses for toner powder, from coloring epoxy resin to making custom t-shirts! Bring the kids! DIY fabric printing fun for all ages!

Printing on fabric at home sounds like a great idea, but how to do it?

Print On Fabric Using Freezer Paper!

☝ What Is Freezer Paper?

Freezer paper is thicker than the regular paper you would use in your printer.

It has a plastic or wax coating on one side that allows it to bond to fabric when heat is applied while still easily peeling off post-printing.

Wax paper is similar to freezer paper, except it has a coating on both sides.

Freezer paper gets its name from the practice of wrapping meat in it for freezing.

Sewing master Lisa Capen Quilts has found a creative way of printing onto fabric at home, using Reynolds Freezer Paper.

Make sure you make a test print first before you ruin your favorite quilt!

How To Print on Fabric at Home Using Freezer Paper:

What You Need for Printing on Fabric at Home

So what do you need to print on fabric at home?

Here’s a checklist:

- Fabric – either bought pre-treated or regular fabric treated with a detergent that will help the ink set.

- Printer – preferably an inkjet printer but laser printers can also work.

- Freezer paper – for bonding to the fabric

- Scissors – for cutting the freezer paper to size

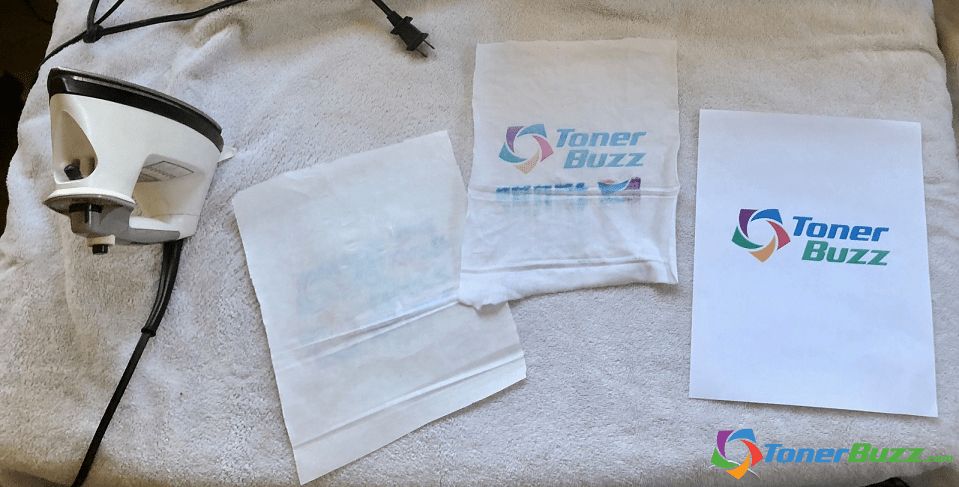

- Iron – for bonding the fabric to the freezer paper

- Vinegar – or another product for helping the ink set post-printing

Our Experience...Does It Work?

Does printing on fabric with freezer paper work?

We decided to give Lisa’s method a try to see if we could duplicate her results.

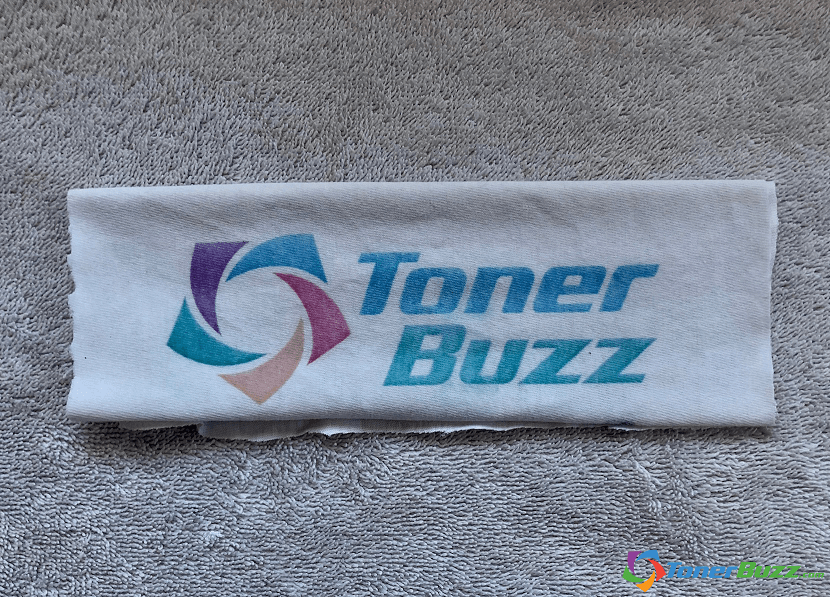

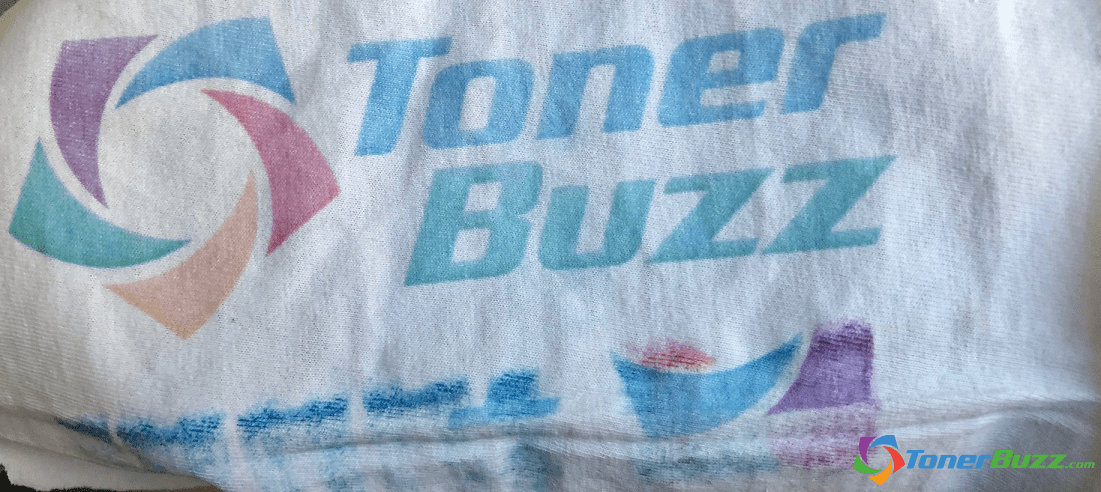

Our verdict...the freezer paper transfer to fabric method works!

But the process was far from smooth, especially for us first-timers.

Our first mistake was not cutting our freezer paper wide enough, limiting us to only one sheet of fabric paper.

Next, we loaded the paper into the printer wrong (duh!) and it jammed on our next attempt.

We should have set our Samsung Xpress Color for thicker paper...and having a manual sheet feeder like Lisa would have helped too.

We loaded the paper wrong again on our third attempt (duh!) but had some success the fourth run through.

The image printed on the fabric, though the paper jammed again on discharge. After printing, the fabric separated easily from the freezer paper.

We were impressed with the results — we could nail this next time! Thanks for the tip, Lisa!

Laser Printing on Fabric or Inkjet Printing on Fabric?

The age-old question in printing: inkjet or laser?

However, this time we’re talking about the best performance when printing on fabric.

First, a quick primer, if you’re not sure what the difference is:

- Inkjet printers use liquid ink applied to the page (or fabric) by micronozzles that deposit tiny drops of ink. Dye or pigment-based inks are available depending on your requirements, and we’ll get into which is the best for fabric printing later.

- Laser printers use toner instead of ink. Toner is a powder that is transferred by an electrostatic charge generated by a laser. Once transferred, the toner is bonded to the surface using heat.

While it is possible to print onto fabric using laser printers, generally speaking, inkjets are the way to go.

This is because toner doesn’t bond to the fabric as well, meaning the colors can rub off easily. Toner is also quite thick, and the fabric becomes stiff and difficult to hand quilt.

This is how printer toner looks. It's dust, not liquid.

Therefore, it is best to only use laser printers for smaller fabric postcards and wall hangings that will be machine quilted.

When using an inkjet printer to print onto fabric, it is important to prepare the fabric to feed through the printer without rippling. You can either buy pre-treated materials for printing or make your own using freezer paper.

Pre-treated fabric generally comes with recommendations from the manufacturer on how to use their products and what steps to take after printing to remove any excess ink.

Making your own printable fabric involves attaching the fabric to freezer paper (as described above), and for good results, you should pre and post-treat it to ensure the ink absorbs and sets correctly without bleeding or fading.

When it comes to choosing what type of ink to use, usually pigment-based inks are superior. Compared to dye-based ink, pigment ink fades less from UV light and offers more water resistance.

How To Print Photos on Fabric

Printing photos on material is generally no different than DIY fabric printing process described in the previous sections.

You can print photos directly onto fabric using the freezer paper method. You’ll need to use high quality white fabric that is tightly woven so the photo transfers successfully.

Before attaching the freezer paper, soak the fabric in a commercial product to help the fabric set and better absorb the ink.

For the photo to print successfully, ensure your fabric is pressed without any wrinkles (likely requires ironing).

Then attach the fabric to the waxy side of the freezer paper using an iron. Backing the fabric with freezer paper gives it some rigidity and allows it to be fed through the printer without rippling.

In order to achieve the best results possible, you will likely need to play around and find the best printer settings.

However, typically you will still want to use the “photo” setting the same as you would when printing photos usually.

Printers That Print on Fabric

There are plenty of options out there for dedicated fabric printing devices. However, they tend to be expensive and aren’t suitable for people looking to experiment with making their own fabric designs at home.

Closer to your standard home printer price range, there are devices like the Epson Surecolor F570.

A desktop device, it was designed for printing on products such as awards, coffee mugs, mousepads and is also great for fabric printing.

If you’re looking to convert a standard home printer to work with fabrics, we’ve already mentioned it is better to use an inkjet printer than a laser. But depending on your specific inkjet printer, results will vary, with some more prone to ink bleeding.

It is possible to get good results for small fabric prints (up to 8.5 inches wide) using just a basic Epson XP-440.

However, if you’re looking to print on larger fabrics, the Epson P400 (printer designed for high-quality photo printing, probably the best printer for fabric printing) works well for fabrics up to 13 inches wide.

Whatever printer you decide to use, make sure you try a few tests first to determine the best settings.

Also, make sure the printer you use is compatible with water-resistant pigment inks that prevent your printed fabrics from fading.

Printing on Fabric FAQ

➜ How to print pictures on fabric? Is printing images on fabric different from printing photos on fabric?

The freezer paper method is the same for images as it is for photos. The only difference may come in how you set up your printer to achieve the best results.

➜ How to print on cotton fabric?

With a bit of experimenting, you can learn how to print on cotton fabric successfully with many standard at-home printers.

Printing onto cotton works the same as with other fabrics; in fact, most believe using 100% cotton fabrics gives the best results.

Generally, heavier fabrics with a thicker weave do not perform as well, and most commercial fabric printables available for your home printing are made from cotton.

➜ How to print letters on fabric?

It can be tricky to print directly onto fabric with enough resolution to use letters or text.

We recommend testing different inks and settings to ensure the results don’t bleed at all. That way, you’ll have the best shot at getting readable text printed onto your fabric.

Calculating arrival date

Calculating arrival date