What is a Fuser?

Posted by Rob Errera on 03/30/2022

What is a fuser inside a laser printer and how long does that part last?

We’re glad you asked!

The fuser unit is a very important component of laser printers. Where would we be without the heat and pressure of the fuser? We’d be left with a blank piece of paper and a bunch of messy toner dust, that’s where. Laser printers depend on the fuser, which is essentially two heated rollers that melt the toner powder onto the paper.

Printer Fuser 101

Laser printers that print on only one side of the paper will have a fuser with only one heated roller. In this case, the second roller — the one on the bottom — is a pressure roller that presses the paper against the heated roller.

A laser printer that can perform two-sided, or duplex, printing will have a fuser with two heated rollers. Both rollers in the fuser get hot and melt the toner powder onto both sides of the page at the same time.

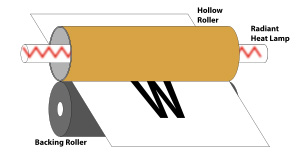

The two rollers inside a fuser work together to melt and fuse the text or image onto a sheet of paper.

How Does A Fuser Work?

At the end of the laser printing process, the paper gets passed through the fuser after the loose toner powder is placed on the paper via static electricity.

Fuser Rollers and Roller Sleeves

During the fuser melting process, the paper is pulled through the two rollers inside the fuser unit. The top roller is very hot and melts the toner particles into the paper. The bottom roller is sometimes also heated such as in the case of duplex (double-sided) printing.

The heated roller is usually made of aluminum with an outer coating of Teflon or some other non-stick material. Over time the heated rollers wear out and need to be replaced. The most common problem is that the outer coating of the heated roller will separate from the inner aluminum tube.

Sometimes the heater roller is covered with a fuser film wrapped around a fuser sleeve. This fuser film can also wear out over time and need to be replaced.

The bottom roller, or pressure roller, is often a solid tube with a rubber coating.

Depending on your printer model, the fuser unit may be sold separately or it may be included in the printer's maintenance kit.

The fuser melts the toner particles, binding them to the page. The speed at which the paper passes through the fuser is what keeps the paper itself from burning. If the speed were slower, the paper would combust and burn. There is also a thermostat built into the fuser that makes sure heat from the fuser never exceeds a certain temperature.

A Xerox fuser.

You can clean the fuser rollers with a clean, dry, lint-free cloth. Fuser rollers can pick up debris and stray particles. Use caution and make sure the fuser had cooled completely before handling it.

If you’ve got the fuser out of your laser printer you might as well clean the pick-up fingers as well. These are the small white hooks that help guide the sheet of paper through the two rollers. Gently lift the pick-up fingers away from the fuser unit and wipe them with a clean, dry cloth or cotton swab. The pick-up fingers are attached to a spring that will snap them back in place.

Speaking of springs, the two rollers inside the fuser are held in place with springs attached to metal clips. You will need to detach the springs in order to change the fuser rollers.

Heater Lamp

The heated roller is hollow and will contain a metal heating element or a halogen bulb inside that gets very hot. Your printer will likely give you an error message when the heater lamp or heating element needs to be replaced. You can tell if the heater lamp or heating element has stopped working because the printer fuser will no longer get hot. Unfortunately, heater lamps are one of the most common fuser parts to fail.

Thermistor

A thermistor controls the heat inside the fuser. Once a certain temperature is reached, the thermistors will signal the heat lamp or heating element to shut off. Your printer will give you an error message if your fuser fails to reach the proper temperature. The thermistor is a type of resistor that touches the heat roller right where the paper enters the fuser. Use a cotton swab to clean any residual toner off the thermistor.

Thermostat

There is also a thermostat built into the fuser that prevents the fuser from overheating. Clean the surface of the thermostat sensor with a clean, dry cloth.

The speed at which the paper passes through the fuser is what keeps the paper itself from burning. Printer fusers can reach temperatures of 420 degrees Fahrenheit or higher. If the speed were slower, the paper would combust and burn.

Gears and Bushings

The gears and bushings on a fuser unit can wear out over time and need to be replaced. Check the gears located on the ends of the fuser rollers. They will likely be made of hard plastic. Make sure they turn freely and none of the teeth are missing on the gears.

Bushings placed between the gear and the rollers can get bent out of shape. If you hear the grinding of metal on metal when your laser printer prints, you may need to replace the bushings.

Electrostatic strip

A strip with a series of metallic tassels is used to discharge electrostatic electricity on the sheet of paper being fed through the fuser. Make sure this electrostatic strip is clean (with a dry cotton cloth) and properly aligned.

When Do I Replace The Fuser?

Fuser units eventually need to be replaced after frequent use. Most laser printers will inform you when the fuser unit needs to be replaced. An easy way to identify when a fuser unit needs to be replaced is when there is smudging or smearing on your printout. Smudging and smearing occur because the fuser will not heat the toner particles enough to fully melt them onto the page.

Signs Your Fuser Is Fading

One sign that you need to replace your fuser is frequent paper jams. Another is a pattern of smudges along the margins of your printouts. Both are signs your fuser rollers are damaged or not properly aligned.

Consequently, you can visually inspect the rollers in your fuser to see if there is any damage to the surface of the rollers. Just make sure that your fuser had completely cooled before handling it.

The life of your fuser depends on the number of pages printed and the amount of toner used. If you’re using your laser printer to print a lot of graphics and photos your fuser will burn out faster.

The size of your printer’s fuser also determines how long it will last before needing to be replaced. Printers with a large fuser can print between 300,000 and 500,000 pages before needing to be replaced. Smaller printers, with smaller fusers, can reach fuser burnout in as little as 50,000 pages.

The printer software included with your printer should be able to give you a report about how many total pages have been printed and how much life is left in your consumables, like your toner cartridges and fuser.

A Final Fuser Tip: Use OEM Toner

One of the differentiating factors for laser printers vs. inkjet printers is the laser printer's use of a fuser. An inkjet printer, as the name suggests, sprays droplets of ink onto a page to form an image or text, while a laser printer uses static electricity to attract toner particles onto a sheet of paper and the heat and pressure of a fuser to melt the toner onto the page.

Also, use genuine OEM toner cartridges in your laser printer. Compatible cartridges won’t have toner specially formulated for your fuser. As a result, the toner may not melt and adhere to the page properly, or, conversely, the toner could “burn” onto the page if the fuser is too hot for the compatible toner powder. Stick with OEM toner cartridges and you won’t have a problem.

Further Reading:

Calculating arrival date

Calculating arrival date